预测性维护

为您的生产效率

提供智能维护。

有了预测性维护,你可以根据数据预测来进行维护工作,不再受固定间隔或指定的机器运行时间的束缚。这使得基于需求的维护成为可能,通过这种方式,你可以减少维修并更大限度地减少

停机时间。这提高了你的计划能力和工厂的可用性,同时减少了与维护、备件和仓储相关的成本。

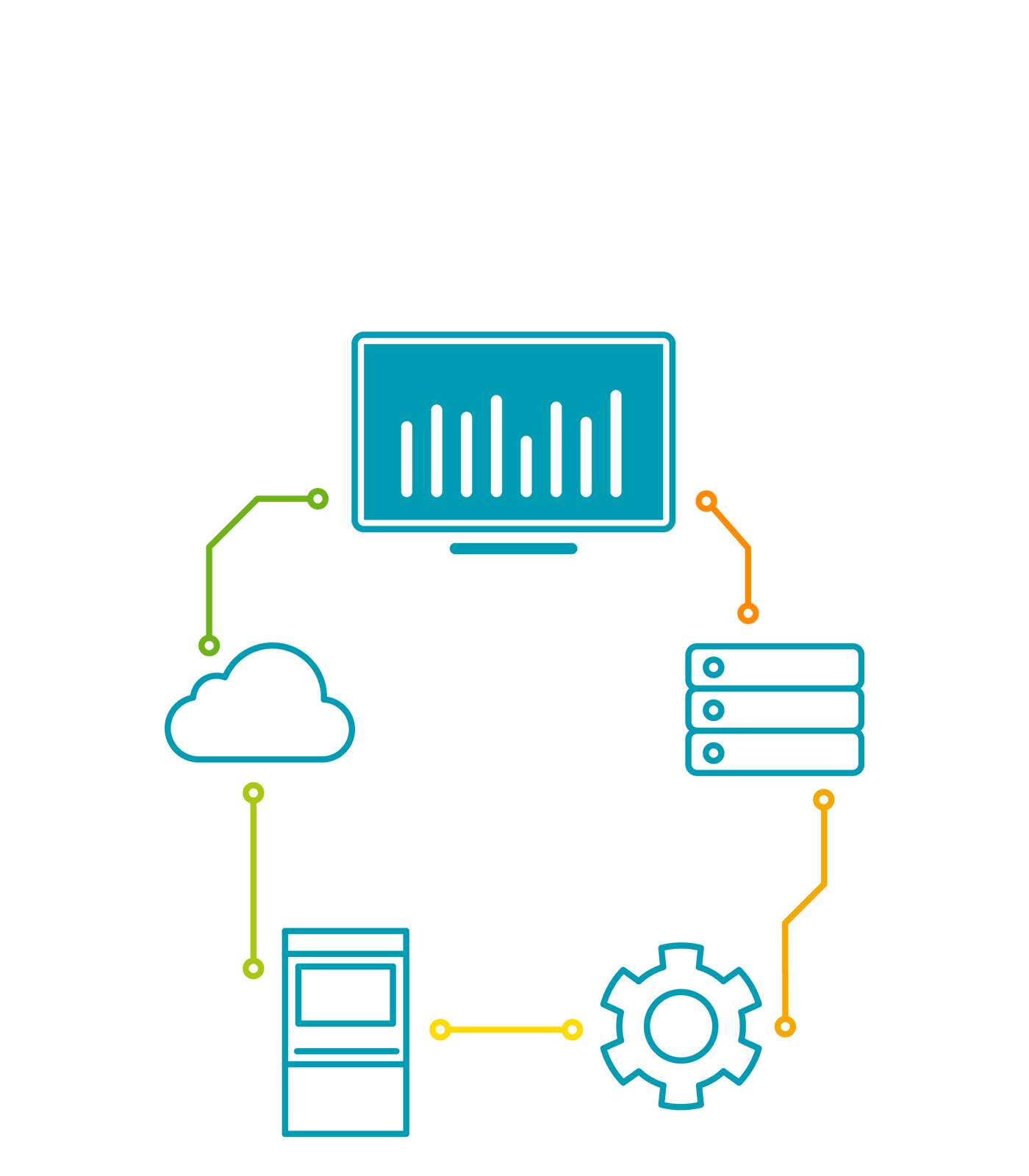

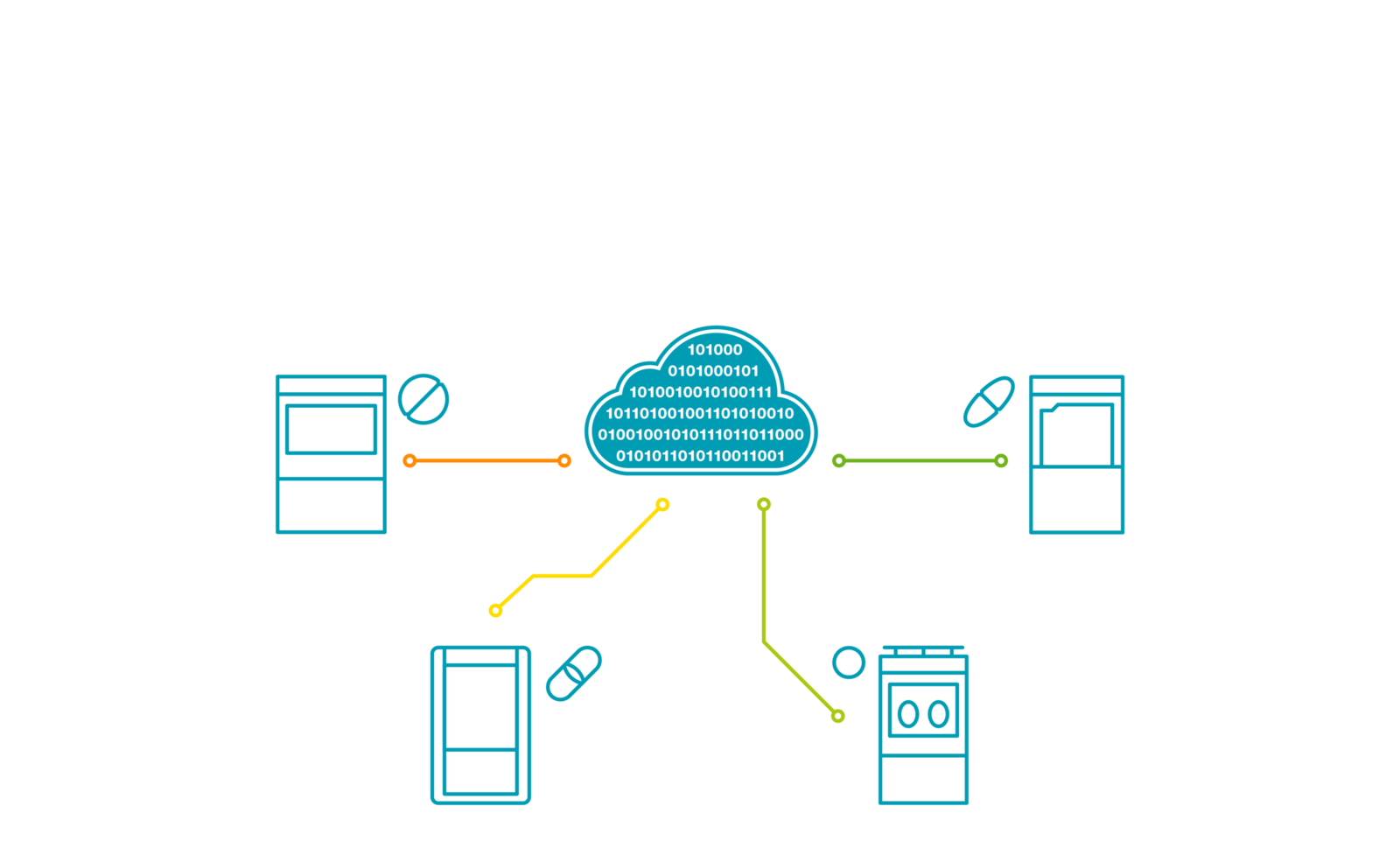

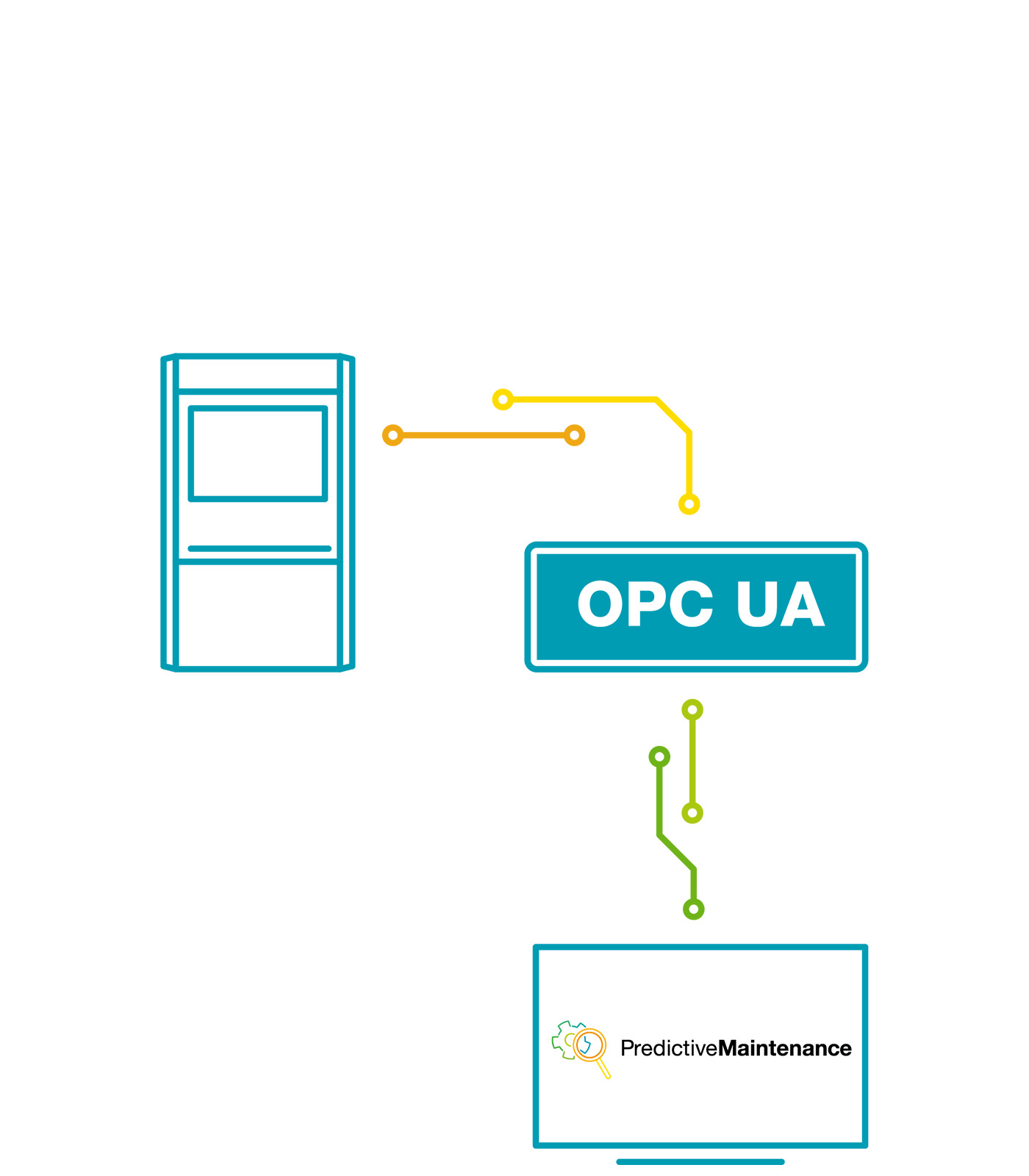

菲特公司已经在研究预测性维护解决方案。组成部分包括机器中的额外传感器技术、基于AI的分析工具以及整合到我们的数字生态系统中。这就是菲特的预测性维护。

正在逐步创建--一个易于使用的应用程序即将推出。

费用

精确控制部件的生命周期,降低了机器的总拥有成本。

可利用性

更准确的预测使维护工作得到更精确的管理,减少停机时间。

灵活性

预测的可靠性和确定性使整个生产过程中的维护操作具有灵活的周期和协调性。

产量

你可以更好地利用你的机器,并优化其使用计划。

仓库

你只在你的仓库中储存符合各自数据情况的、在不久的将来会需要的零件。

持续性

你节约了资源,从而改善了你的生态足迹。

在未来加入我们!

预测性维护是一个创新的转型项目,正在向数字化的未来迈进。早在开发阶段就成为它的一部分! 作为菲特公司的合作伙伴,你将成为第一推动者,并可以为项目提供你自己的要求。项目。实现您的竞争优势。让我们来谈谈合作!

公司的数字企业家精神。

基于人工智能的维护策略最需要的是:数据。

受益于对已有数据的系统化访问,并通过额外的传感器丰富其参数。记录每个维护周期的磨损和备件的运行时间。

通过这种方式,你为算法和模型建立了坚实的基础,预测性维护可以在未来在你的公司中充分展现其潜力。

共同实现更多目标。

当我们从一开始就紧密合作时,预测性维护的效果最好。菲特公司帮助你打好基础,在你的公司建立这种新型的维护。

- 我们支持您说服其他利益相关者转用预测性维护的好处。

- 我们与您一起,建立必要的接口。

- 我们为您提供必要的传感器技术并帮助您进行安装。

- 我们一起开发用于评估数据的用例和模型,以获得与您相关的见解。

- 我们帮助你定义关键绩效指标,你可以用这些指标来评估与我们合作的试点项目是否成功,并衡量其附加值。

性能概览

我们使您在数据处理方面做好数字化准备。我们的机器和应用知识以及您的特定产品能力为您未来的数字化工厂奠定了基础。

性能概览

状况监测器帮助你轻松控制和优化机器的性能。

我们期待着对话。

请与我们联系,成为通向未来OSD生产道路上的先行者。

全球销售

菲特(中国)制药科技有限公司

江宁区盛通路9号

南京市,江苏省

中国