Highlights of the Series.

Innovation and new standards in capsule filling machines. Fette Compacting has also been a major player in efficient capsule production since 2016. Maximum production performance combined with extremely easy operation and minimization of machine downtimes.

Flexible set-up

The capsule filling machines are fully driven by servo and torque motors. This enables process steps which were previously coupled to be set independently. Users can also individually adapt the strokes of the tamping pin station and closing station during ongoing production. No additional mechanical adjustments are required after conversion or cleaning.

Flexible set-up

Flexibility, which saves time and money. Without any compromises on quality.

NMC sensor

Absolute precision is critical for capsule filling with high-performance machines: each capsule must contain the identical quantity of product. This calls for a method of measurement that works at high cycle rates without loss of performance. The NMC (Net Mass Control) sensor meets this demand. It is based on a contactless, capacitive measuring technique in which an electric field captures the metered quantity during the dosing. The sensor continues to deliver 100 percent results where gravimetric scales come up against their limits.

NMC sensor

Capsules dosed precisely and efficiently.

The filling process in five steps

Feeding, separating, filling, closing and discharging the capsules.

Best in batch-to-batch

The capsule filling machines are fully driven by servo and torque motors. This enables process steps which were previously coupled to be set independently. Users can also individually adapt the strokes of the tamping pin station and closing station during ongoing production. No additional mechanical adjustments are required after conversion or cleaning.

Best in batch-to-batch

Format changes have never been faster – thanks to innovation! Experience one of the fastest format changes on the market.

TRI.EASY

One stand-alone feature of the FEC Series is its tamping pin station removal system. Like the pellet station available as an alternative, the tamping pin stations can be dismantled and cleaned outside the machine.

The result: much shorter changeover and cleaning times.

TRI.EASY

Easy cleaning, perfect handling and fast changeover.

Your success counts!

What distinguishes the best capsule filling machines? The contribution they make toward your economic success. Everything is primed for this in the FEC Series. Benefit from our technology, our service and our consulting competence!

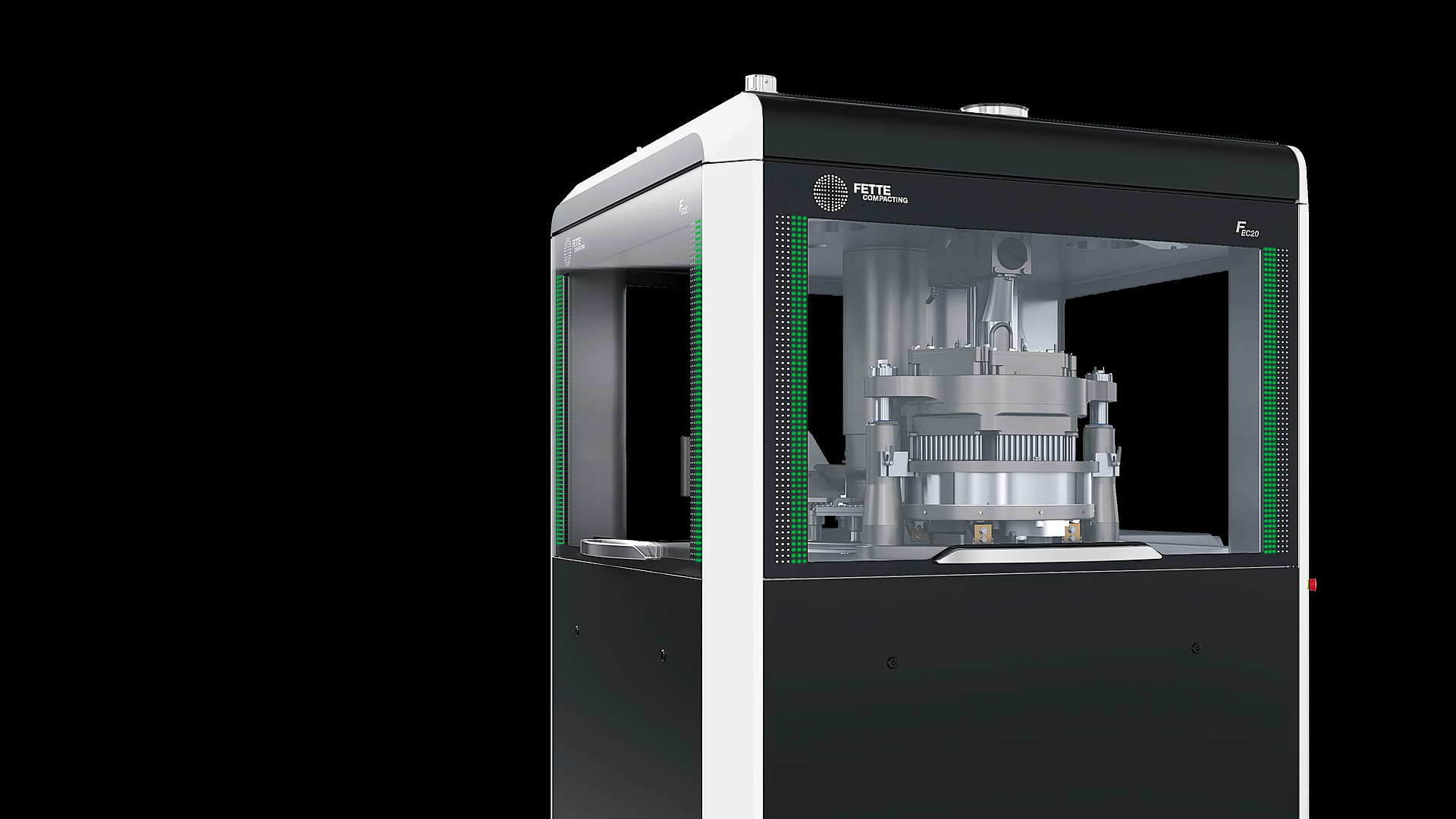

FEC20

Designed for medium-sized batch charges.

DownloadSpecial features

Easy exchanges of many parts with the FEC40

Compatible with SmartInterface

Stations

9

max.

Capsule output

200,000

max. per h

Capsule sizes

000 to 5

Dimensions and Weight

| Height | Width | Depth | Weight |

| 2,068 mm | 1,648 mm | 1,648 mm | approx. 3,500 kg |

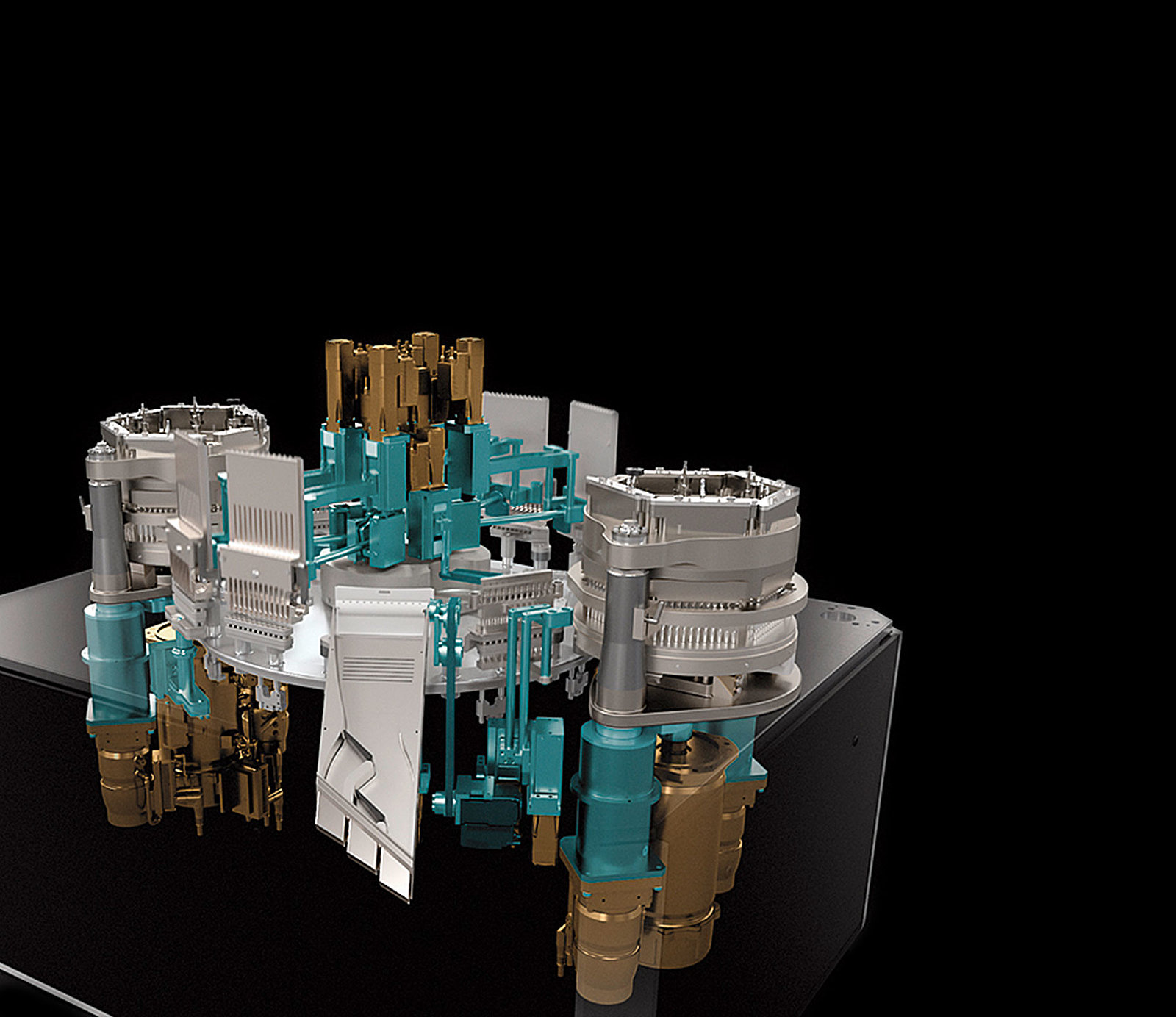

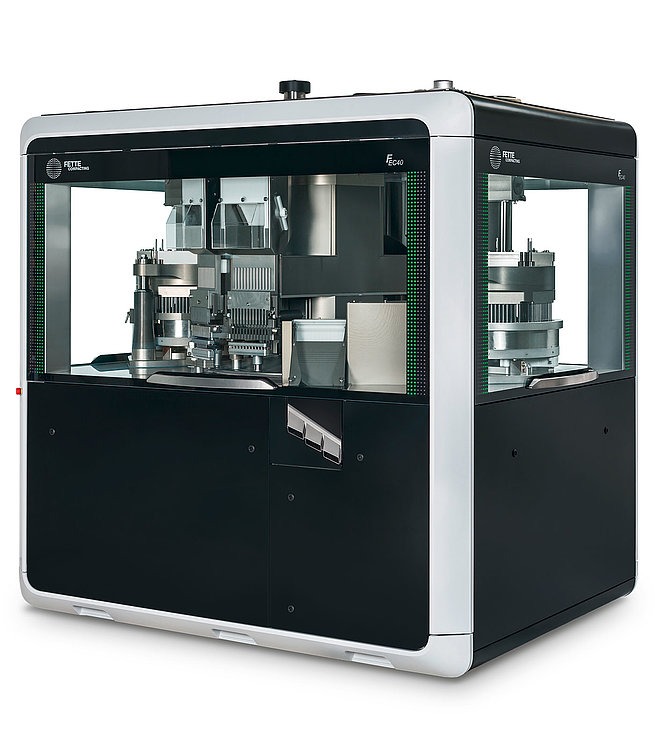

FEC40

Designed for extremely high output.

DownloadSpecial features

Duplex Concept permits two capsule filling processes on the same floor area

Production costs reduced by up to 30 percent

Compatible with SmartInterface

Stations

12

max.

Capsule output

400,000

max. per h

Capsule sizes

000 to 5

Dimensions and Weight

| Height | Width | Depth | Weight |

| 2,068 mm | 2,148 mm | 1,648 mm | approx. 4,500 kg |

What is and will

continue to be important.

Articles and reports on current developments and technological innovations. For even more efficiency!

Want to know more about the FEC Series?

Please do not hesitate to contact us if you require more information and detailed advice. We look forward to receiving your phone call or email.

Global Customer Support

Fette Compacting GmbH

Grabauer Str. 24

21493 Schwarzenbek

Germany

Technical Customer Support